The global cargo shipping industry is vast, with a market valuation reaching an astonishing $16.7 billion. Yet, a sobering fact lurks beneath the surface: annually, goods worth $500 billion fall victim to container – related damage. Among these losses, moisture accounts for at least 10%—a significant figure that can disrupt supply chains and erode business credibility.

Moisture – induced damage isn’t just a theoretical concern; it’s a tangible threat that demands foolproof solutions. The consequences extend beyond mere product degradation; they can taint a company’s hard – earned reputation. Container desiccants have emerged as a globally recognized safeguard against moisture – related harm. However, the common misconception that purchasing desiccants is the end – all – be – all couldn’t be further from the truth. In reality, effective moisture protection is a two – pronged approach: half lies in procuring quality desiccants, and the other half hinges on proper utilization.

The efficacy of container desiccants is directly tied to adherence to specific best practices. Overlooking these guidelines can lead to significant financial setbacks. To ensure optimal protection for your shipped goods, here is a comprehensive guide to the dos and don’ts of using desiccant materials in cargo containers:

Dos When Shipping Cargo Containers with Desiccant Materials

1. Make an Informed Desiccant Selection

While all desiccants share the primary function of moisture absorption, their properties and benefits vary widely. Tailoring your choice to the unique requirements of your cargo and shipping conditions is paramount.

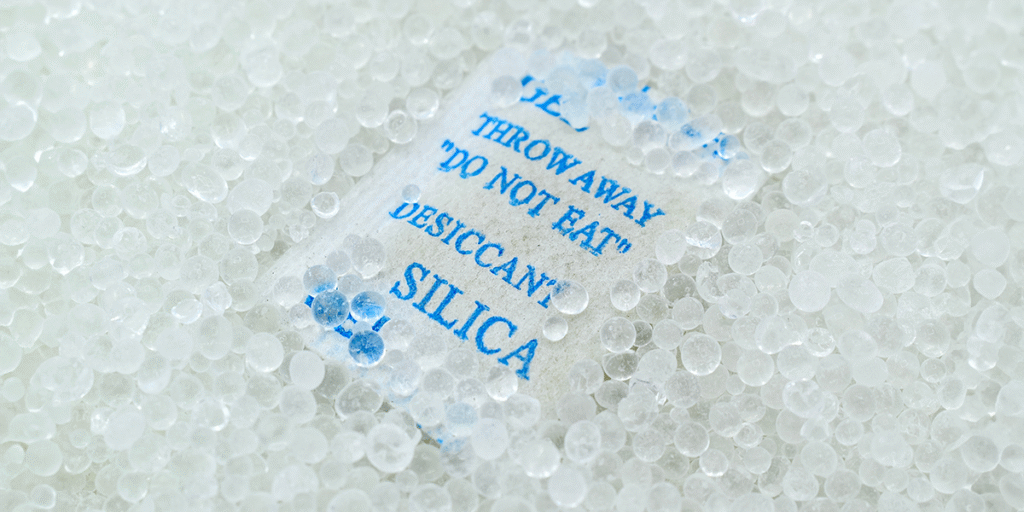

- Silica Gel: Capable of absorbing up to 40% of its weight in moisture, silica gel is the go – to option for humidity – sensitive items. Electronics, clothing, footwear, pharmaceuticals, and packaged food benefit greatly from its precise humidity – control capabilities. It performs best in moderately humid environments.

- Calcium Chloride: With an impressive absorption capacity of up to 300% of its weight, calcium chloride excels in high – moisture scenarios, such as ocean freight or during rainy seasons. It’s particularly well – suited for safeguarding bulk cargo like machinery, metal parts, and large – scale shipments.

2. Implement Strategic Placement

Randomly placing desiccants within a container undermines their protective potential. Thoughtful positioning and even distribution are essential for effective moisture absorption and prevention of “container rain”—a phenomenon where condensation forms inside the container and damages goods.

Corners of the container tend to accumulate more moisture, making them prime locations for desiccant placement. Some modern desiccants come equipped with innovative hooks, facilitating quick and hassle – free installation.

3. Ensure Rigorous Container Sealing

Desiccants operate at peak efficiency in a sealed environment. Double – check that container doors are securely locked, leaving no room for air or moisture infiltration. Conduct a thorough inspection of the container for any signs of damage, including dents, rust, or cracks. Pay close attention to the floor, roof, and sides to ensure a watertight seal.

4. Monitor Temperature Fluctuations

Weather conditions during shipping are unpredictable, and temperature variations can trigger “container rain.” As the container travels through different climates, maintaining a stable internal temperature or adjusting the amount of desiccant can help mitigate this risk. Regularly monitor temperature changes and be prepared to take corrective action.

5. Conduct Pre – Conditioning

Before embarking on a long – distance journey, especially in extreme weather, pre – conditioning the container enhances its reliability. This process involves drying the interior of the container using methods such as ventilation, dehumidifiers, or preliminary desiccant application. A dry start significantly improves the effectiveness of desiccants during transit.

Don’ts When Shipping Cargo Containers with Desiccant Materials

Container desiccants offer robust protection against moisture, but their effectiveness can be compromised by improper usage. To avoid potential pitfalls, keep the following precautions in mind:

1. Steer Clear of Low – Quality Desiccants

The desiccant market is flooded with options, but quality should never be sacrificed for cost. Opt for high – grade desiccants manufactured with premium materials and sealed using ultrasonic technology. Low – quality desiccants may fail to absorb moisture adequately, leading to condensation and cargo damage.

2. Don’t Guess the Desiccant Quantity

Estimating the amount of desiccant needed based on assumptions can be costly. Instead, consider factors such as the required level of moisture protection, the duration of the shipment, and the expected climate conditions. Using too little desiccant leaves goods vulnerable, while excessive use results in unnecessary waste.

3. Don’t Neglect Regular Replacement

The lifespan of cargo desiccants ranges from 1 to 5 years, depending on the type and packaging quality. However, their moisture – absorbing capacity diminishes significantly within 48 hours of exposure to air. Regularly monitor the desiccant’s shelf life and replace it as needed. Even without a clear manufacture date, visual cues can indicate when replacement is necessary—crumbling or brittle desiccant beads are a sure sign of reduced effectiveness.

4. Avoid Improper Placement

In addition to strategic positioning, maintaining a proper distance between desiccant bags and goods is crucial for maximum moisture absorption. Ensure that the desiccants can be easily removed upon arrival without causing damage to the cargo.

5. Don’t Skip Post – Arrival Inspection

Once the shipment reaches its destination, inspecting the desiccant is essential. This evaluation provides valuable insights into the desiccant’s performance, saturation levels, and overall suitability for the shipment. Failing to conduct this inspection means missing out on critical information that can inform future desiccant selection and usage.编辑分享

How can we effectively prevent moisture damage during cargo shipping?

Are there any innovative packaging materials available to combat moisture?

What are the best practices for handling and storing goods to minimize moisture exposure?